Need a guidance to implement QR codes in your company’s inventory management? This article is for you. QR Codes contain complete data, ranging from product details to exact location information and stock level tracking. By incorporating QR codes, you can increase accuracy and reduce errors when managing inventory in warehouses, retail outlets, etc. This technology enhances ordering processes, minimizes waste, and ensures seamless operations for overall management. This article unravels the benefits, ideas, and procedures to create a QR code and use it in inventory management.

Table of Contents

Why Use QR Codes for Inventory Management?

QR codes are easily scanned using smartphones, making them convenient for inventory management. There’s no need to purchase expensive scanners as QR codes are scannable with mobile devices. It can store and display a wide range of data, including PDFs, images, and videos. It even functions when slightly damaged due to built-in error correction features.

Dynamic QR codes lets you update and change the information linked to the code at any time. QR codes are not tied to a computer and can be used in any location with a smartphone. It seamlessly integrates with existing inventory management systems, offering a straightforward upgrade.

How to Create QR Code for Inventory Management

With URLSRT’s QR code generator, you can create customized QR codes for your business. We offer tracking features so you can see which QR codes are highly used and performed.

1. Go to the urlsrt.io on your device browser.

2. Select the Get Started button and log in with your account credentials. If you are a new user, then select the Register button to sign up for a new account.

Tips! In addition to the QR code, you can use our tool to shorten the links for free and without a registered account.

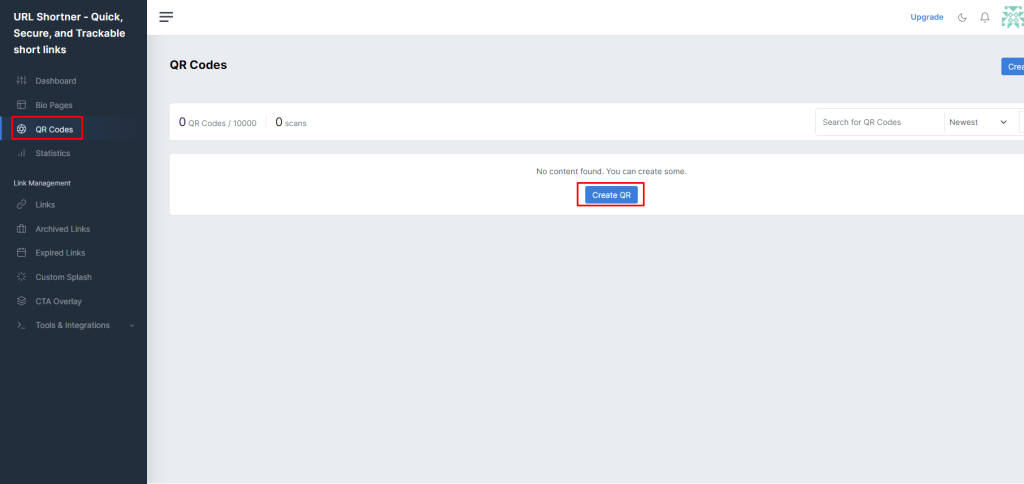

3. Launch the Dashboard and navigate to the QR Codes tab.

4. Click on the Create QR button and name the QR code in the required field.

5. Choose the Dynamic QR and provide the essential details in the column.

6. Overview the code by selecting the Preview button; after that, select Generate QR.

7. Pick the file type from the options and click Download to download the QR code.

Note: If you want your QR codes to look different, you can customize them from the Colors and Design section on the page.

Tips for Creating QR Codes for Inventory Management

To create efficient QR codes for inventory management, it’s important to plan thoughtfully and pay close attention to details.

- Dynamic QR codes are widely preferred for inventory management due to their trackability and ability to be updated.

- Customizing QR code designs helps differentiate product categories and promote branding.

- Implement regular inventory checks and database updates to maintain accuracy and efficiency.

Ways to Implement QR Codes for Inventory Management

The following are different innovative techniques to deploy QR codes to manage your inventory.

- Retail: Helps maintain accurate stock information and engage customers with links to online promotions.

- Healthcare: QR codes track medical supply levels and locations, enabling efficient resource management.

- Logistics and Warehousing: It provides live data for precise control and optimization of ordering and shipping.

- Manufacturing: Aid with tracking complex parts and equipment maintenance for better risk compliance.

- Libraries: Add rich data layers for book and resource management, enhancing the patron experience.

- Event Management: Simplify the inventory tracking for events, aiding in the management of supplies and equipment.

Merits of Using QR Codes in Inventory Management

QR codes bring advantages to inventory management, simplifying processes and delivering up-to-date data for effective stock monitoring.

- Quicker scanning and inventory data updates: QR Codes enable faster scanning from multiple angles, leading to efficient work processes.

- Increased accuracy: It offers built-in error correction for accurate scanning even when partially damaged.

- Versatility in various environments: QR codes are adapted to various conditions, from printed materials to digital displays and even carved steel.

- Better data management: Store detailed data for improved inventory organization and future business analysis.

- Real-time tracking: Provides real-time data updates, allowing teams to monitor inventory and anticipate issues.

- Streamline inventory process: Understanding the inventory’s specific needs helps to determine which data to track for effective management.

Frequently Asked Question

You can read QR codes in the vertical and horizontal directions, and they can store over 2500 characters, whereas barcodes can store only 25.